Casing Oscillators for cable excavator attachment

Hydraulic oscillators are used when the torque of conventional drilling drives is insufficient or the use of rotary drilling rigs is uneconomical, for example in the case of large drilling depths or high casing friction due to the subsoil. Furthermore, it is used when the pull-back force of the carrier is not sufficient for pulling the casings. Our experience from decades of cooperation with contractors in the field of special civil engineering has always been incorporated into the improvement and further development of our machines. LEFFER stands for solid machines and profitable construction site operations.

| Grab Drilling | Casing Oscillators in mm | Lifting force in N | Torque in kNm | |

| VRM 1300 | 620–1300 | 1530 | 1660 | |

| VRM 1500 | 750–1500 | 2050 | 2900 | |

| VRM 2000 | 1180–2000 | 2650 | 4110 | |

| VRM 2200 | 1500–2200 | 2650 | 4520 | |

| VRM 2500 | 1800–2500 | 5150 | 9500 | |

| VRM 3000 | 2000–3000 | 9000 | 13500 | |

| VRM 3300 | 2500–3300 | 10860/11780 | 19900/23000 | |

| VRM 3500 | 2500–3500 | 10860 | 22000 | |

| VRM 3800 | 2800–3800 | 8310/8310/11780 | 15800/22000/31000 |

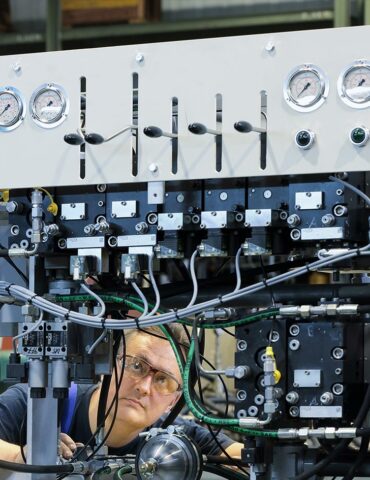

Hydraulic Power Packs

To increase the performance and improve the flexibility of our casing oscillators and casing rotators, separate hydraulic power packs adapted to our machines can be used. We attach great importance to components from renowned manufacturers in order to be able to guarantee trouble-free operation and the best possible availability of spare parts via the international dealer network. To ensure continuous operation under extreme loads, the cooling capacity of the power units has been optimized. Exhaust emission standards for the drive engines are met, as are the lowest possible noise emissions for work in noise-sensitive areas. To ensure economically optimal service interventions, all components are arranged according to the best possible accessibility.

| Hydraulic Power Pack | PP 205/75 | PP 400/270 | PP 800/420 | PP 1000/570 | PP 1200/630 |

| Engine | Hatz 4H50TICD | Caterpillar C7 ACERT | Caterpillar C13 ACERT | Caterpillar C18 ACERT | Caterpillar C18 ACERT |

| Power in kW (PS) | 55 (75) | 201 (270) | 313 (420) | 420 (570) | 463 (630) |

| Pump flow rate in l/min |

2 x 125 (1 x 250) |

2 x 200 | 2 x 400 / 2 x 106 |

2 x 520 | 2 x 600 |

| Use | VRM 1000 – VRM 1200 / VRM 100 KL – VRM 120 KL |

VRM 1500 – VRM 2200 / VRM 150 KL – VRM 250 KL |

VRM 2500 – VRM 3000 |

VRM 3000 – VRM 3800 |

VRM 3500 – VRM 3800 |

Single-rope and double-rope spherical grabs and pulley grabs

The drilling and construction progress in projects depends not only on the machines used, but also quite significantly on reliable tools. For cased pile foundations, a robust drilling grab is essential. LEFFER has developed three robust digging grabs with high impact force for sinking boreholes in rocky, rolling soils and for working under water superimposed loads:

The single-rope pulley grab is particularly characterized by its oil-filled bearings, which remain maintenance-free over the entire service life. The design of the two-rope grab is similar, but does without a pawl carrier and release crown. Lifting and lowering of the grab is controlled by the first rope, the so-called drive rope. The second rope (closing rope) is used for opening and closing.

With this design, the operator can also open and close the grab several times during the drilling process – for example, to loosen the ground or to empty the grab in very cohesive soil. If very large closing forces are required, the use of spherical grabs is recommended. Due to its high intrinsic mass and additional teeth on the spherical shells, the spherical grab can dig into the ground during the closing process and exert very high splitting forces on the ground to be loosened.

Hydraulic spherical grabs

For partially or uncased drills and/or when vibration-free drilling is required, the hydraulic spherical grab is used. Several hydraulic cylinders in the body of the grab provide high closing torques. In combination with its large dead weight, this ensures a constantly good filling level of the grab buckets. The hydraulic rotary drive allows controlled rotation of the drilling grab around the vertical axis by ± 100°. In order to detect and counteract deviations from the vertical axis, all LEFFER hydraulic grabs are equipped with a 2-axis inclinometer. A simultaneous display in the operator‘s cab of the carrier provides additional support during calibration – especially for uncased drills.

| Grabs | Hydraulic spherical grabs | Single-/Double-rope spherical grab | Single-/Double-rope scissor grab | |

| Ø D (mm) | 880 – 3660 | 600 – 3000 | 470 – 2000 |

Single-/double-rope scissor grabs

LEFFER’s scissor grab is a top-of-the-line universal drilling grab that has proven itself under a wide variety of requirements. Instead of using rope pulleys, this grab closes with a scissor system that operates with very little wear. A pre-tensioned spring is used to open the buckets and also ensures that adhering drilling material is ejected.

The shape of the grab body has been designed so that high fall speeds can be achieved even when drilling in water. Additional side pockets on the lower part of the grab increase the filling volume of the shovels in soft soils.

Chisels

Chisels are used when drilling in very hard soils or rock and for piercing through drilling obstacles. They can also be used in cohesive soils for pre-cutting in order to be able to penetrate better with a piercing tool afterwards. The cutting edges of all LEFFER chisels are made of high-strength steel (Hardox 450). This guarantees high wear resistance in combination with high cold bending strength.

Reach out to us!

LEFFER machines offer you the right combination of power,

accuracy, robustness and reliability. Our worldwide customer service is guaranteed by our service agents.

Accessories

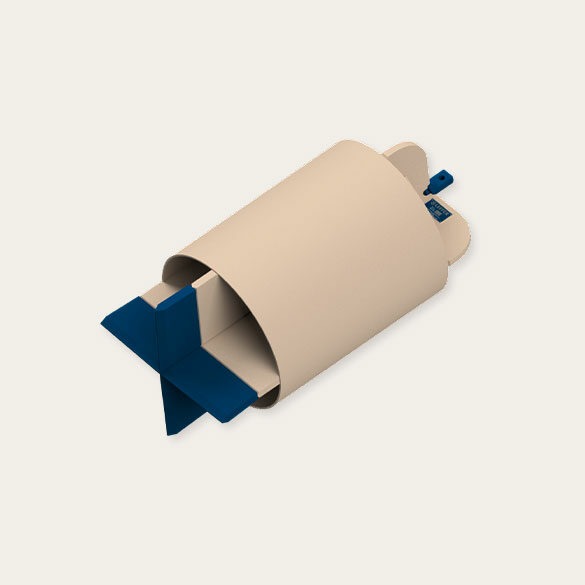

Casings

For cased boreholes, LEFFER offers double-walled casings in different of useful lengths. Our low manufacturing tolerance for diameter, roundness and straightness pays off on the construction site: Precisely fitting casing joints ensure fast, straight placement, bolting and optimum force transmission. The casing joints, consisting of a female and male part, are secured with radially arranged conical bolts. The inside and outside of the casings are smooth throughout their entire length, which prevents the reinforcement cage or drilling tool from getting stuck when pulling the casing.

LEFFER casings have also proven themselves many times over in cased kelly drilling through water-bearing soil layers or in drilling with water ballast. To prevent water and fines from entering the casing, both the cone bolts and the casing joints can be sealed with additional sealing rings.

HD Casings

For cased boreholes greater depths or diameters greater than 1500 mm, LEFFER HD has casings in its portfolio that meet the high requirements for particularly large drilling depths. Reinforced casings joints with backlash-free, conical bolts and larger wall thicknesses reduce wear on the casings joints and also ensure reliable transmission of vertical forces and torque.

| Casings | HD Casings | |||

| 620/540 | 1500/1400 | |||

| 750/670 | 1800/1700 | |||

| 800/720 | 2000/1880 | |||

| 880/800 | 2200/2080 | |||

| 900/820 | 2500/2380 | |||

| 1000/920 | 2800/2640 | |||

| 1200/1120 | 3000/2840 | |||

| 1300/1220 | 3200/3040 | |||

| 1500/1420 | 3500/3340 |

Cutting shoes

Decades of practical experience are incorporated in the design and continuous further development of our cutting crowns. For continuous drilling, the tooth system, i.e. tooth shape and number, contact pressure and the corresponding free cut must be correctly selected. The geology of the ground determines the design of the cutting teeth. Taking these variables into account, LEFFER offers individual cutting crown types for a wide range of requirements.

Tremie pipes and accessories

When concreting there is a risk of the concrete segregating in the downpipe. To ensure a safe concreting process, LEFFER has developed a special HD concreting tremie pipe system: The tremie pipe joints we have designed can resist very high tensile forces, which prevents the concreting pipe string from tearing off, even in case of very long pipe strings. The high-precision, machine-manufactured parts have a high degree of tightness and are therefore also ideally suited for applications in the field of air-lifting technology.

The reduction of individual parts (in contrast to flanged pipes) reduces wear at the joints. Easy to handle, maintain and (dis)assemble, LEFFER tremie pipes NW 150, 200, 250 and 300 save valuable time and thus costs at the construction site.