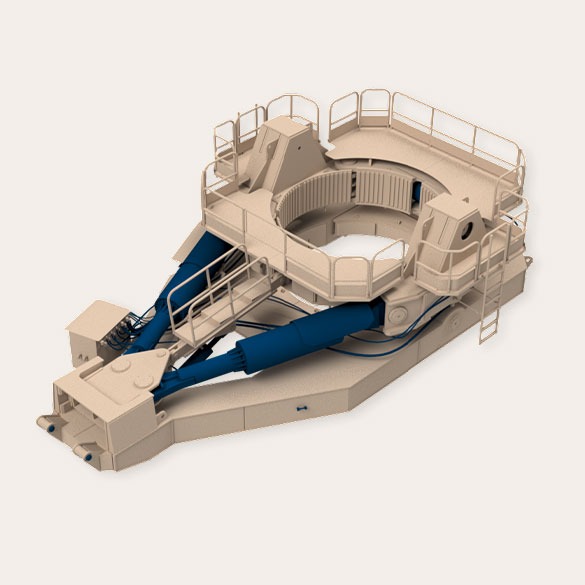

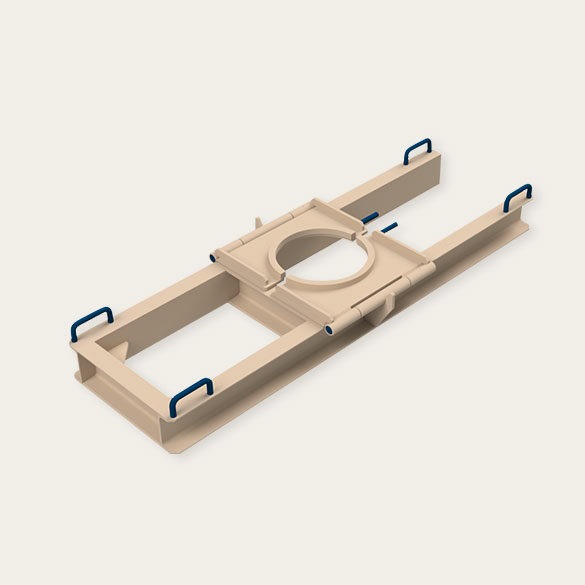

Casing machines KL type for combined use rotary drilling rigs

To support the rotary drilling rig, LEFFER offers casing oscillators in short design (KL type). In general, the LEFFER casing oscillators have been designed according to special empirical values:

- The five-link clamp, which encloses the casing, prevents plastic damage to the pipe circumference and ensures efficient and force-locked transmission of torques and vertical forces.

- Our casing machines can be converted to smaller diameters in a matter of minutes thanks to our reduction inserts.

- The torque-resistant attachment to the excavator guarantees the transmission of the full oscillating movement. This allows rotation of the pipe string up to 25° per oscillating movement.

- The low headroom on the excavator side allows a 360° movement of the excavator upper carriage even when coupled.

- LEFFER casing machines can be used to case and drill at the same time. It is controlled either via the on-board hydraulics of the carrier device or via a LEFFER-own unit.

| Casing machines | Drilling diameter in mm | Lifting force in N | Torque in kNm | |

| VRM 100 KL | 500–1000 | 920 | 800 | |

| VRM 118 KL | 620–1180 | 1200 | 1250 | |

| VRM 120 KL | 620–1200 | 1200 | 1250 | |

| VRM 130 KL | 750–1300 | 1700 | 1600 | |

| VRM 150 KL | 750–1500 | 1700 | 1850 | |

| VRM 200 KL | 1200–2000 | 2250 | 2700 | |

| VRM 220 KL | 1500–2200 | 2250 | 2900 | |

| VRM 250 KL | 1800–2500 | 2950 | 3250 |

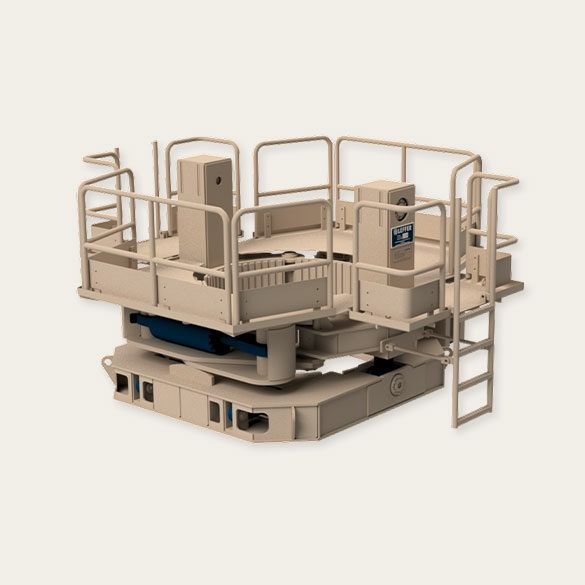

Casing extractors machine

When completing piles in the diameter range 600 to 1500 mm, the use of a a rotary drilling rig is often inefficient. Crane work is required to install the reinforcement, tremie pipes as well as during the subsequent concreting process, for which the drilling rig is only equipped with an auxiliary winch.

To ensure safe retraction of the casings, very large drilling rigs are used uneconomically, deliberately avoiding the use of a casing machine. For larger construction projects, it is therefore more economical to use a drilling rig exclusively for the production of the cased borehole and a crane with a compact LEFFER casing pulling machine for the completion of the pile.

Electric automatic rotary adapter

Drilling rigs of the latest generation deliver very high torques, which increasingly means that cased holes can be drilled even to greater depths. For this purpose, longer and longer casings are used, where the rotary adapter must be locked at great heights. It is also sometimes necessary to „untwist“ the casing by pulling it back, which makes it necessary to lock the adapter while the casing is still being brought down.

The manual locking and unlocking of the adapter with the casing is very time-consuming – it also involves risks for the personnel on the construction site. Our solution is the E-ADT: Electromechanically operated and controllable via a radio hand-held transmitter, it eliminates the need for manual locking and unlocking. Operating functions and operating states are signaled and monitored via the hand-held transmitter. The standard scope of delivery includes 2 rechargeable batteries with a long service life to completely avoid downtimes.

Hydraulic retaining clamps

Retaining clamps are used in the rotary drilling process to prevent the drill string from slipping when the casing is pulled after uncoupling from the adapter. The hydraulic retaining clamp SPA can be supplied via a carrier unit or via a separate hydraulic power pack (E-PP5). The clamping cylinder with load holding valve ensures that the casing string is held securely.

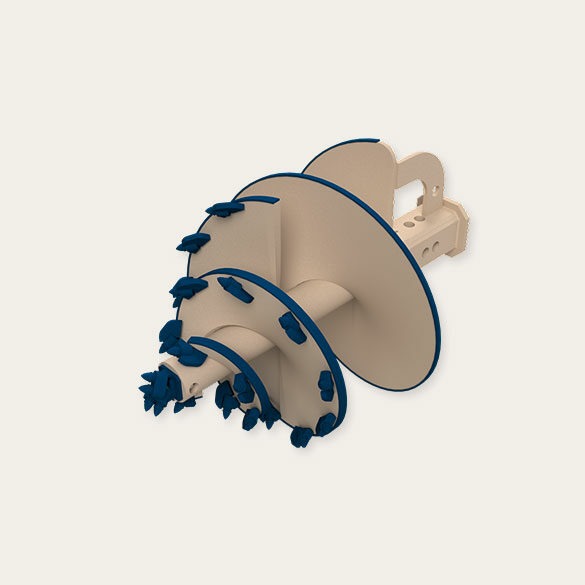

Augers

Augers are used for loosening and conveying dry ground or rock. For drilling in dry ground, LEFFER offers a wide range for dry drilling variants for optimal processing of the subsoil:

The number of cutting edges, the pitch of the auger helix and the type and number of teeth or bits vary depending on the soil conditions. For better guidance of the auger, the augers are additionally equipped with calibration bits. Wear strips reduce the abrasion on tooth holders and auger flights. We recommend our types BS and BS-1 for soft soil layers and BSF, BSFoP, BSP and BSP-2 for hard soil layers.

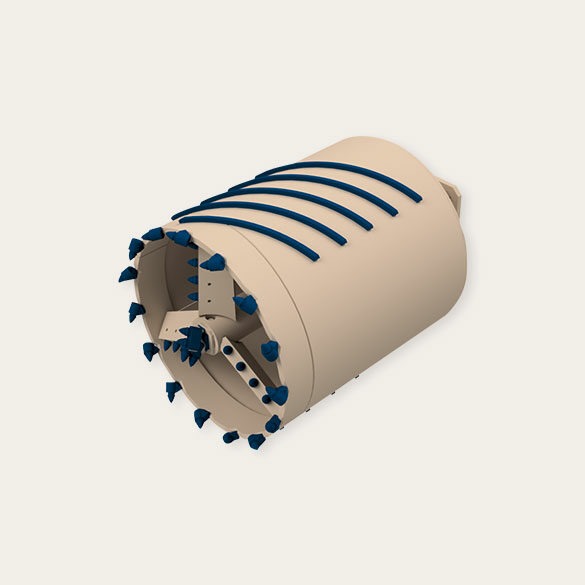

Drilling buckets

The drilling bucket is used when drilling in water, supporting liquid or very soft, cohesive soils. It also ensures a flat cleared borehole bottom. The revolving segment can be opened by turning it to the right (locking direction of the kelly bar) to feed material into the drilling bucket. The filled drilling bucket is closed by turning it to the left (unlocking direction of the kelly bar). For optimal processing of different drilling grounds, the drill bucket can be equipped with different cutting edges, pilot drills, toothed bits or chisels on the underside. For cleaning the bottom of the borehole, a bucket without pilot bit, but with reamer bar, is suitable. Drilling buckets with single-bladed revolving segment with flat teeth are used in soft to semi-solid cohesive soils as well as non-cohesive soils up to dense bedding. For larger diameters (from approx. 1.5 m) and for uncased boreholes, the drilling bucket should be equipped with two cutting edges. To avoid suction (piston effect) while pulling the drilling bucket, LEFFER drilling buckets are equipped with a flow channel. In the case of smaller versions, the bucket is closed by means of a rotary heart locking mechanism; in the case of large diameters, by means of a hook-locking mechanism. For soft soils we recommend our types BE and BE-2, for hard soils the types BEF, BEF-2 and for clearing the bore bottom BER.

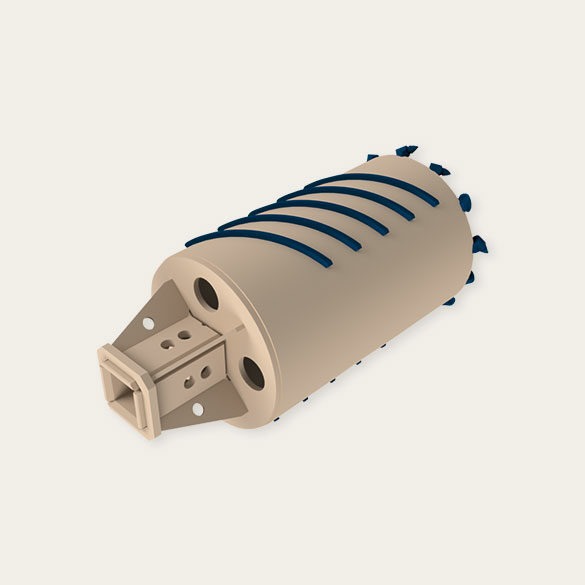

Core barrels

Core barrels are used to cut an annular space in hard rock, boulders or concrete. In order to break the upcoming material with high tension, torque and feed force are concentrated on a relatively narrow ring. Depending on the strength of the rock and the drill diameter, the toothing of the core barrel can be adjusted: For concrete and rock with unconfined compressive strengths up to approx. 100 MPa, core barrel with welded-on carbide pins or studs are used. Alternatively, core barrel with round shank bits are suitable for this purpose. For drilling in compact rock with unconfined compressive strengths from 100 MPa to over 250 MPa, LEFFER core barrels with roller bits have proven to be the best choice.

Reach out to us!

LEFFER machines offer you the right combination of power,

accuracy, robustness and reliability. Our worldwide customer service is guaranteed by our service agents.

Accessories

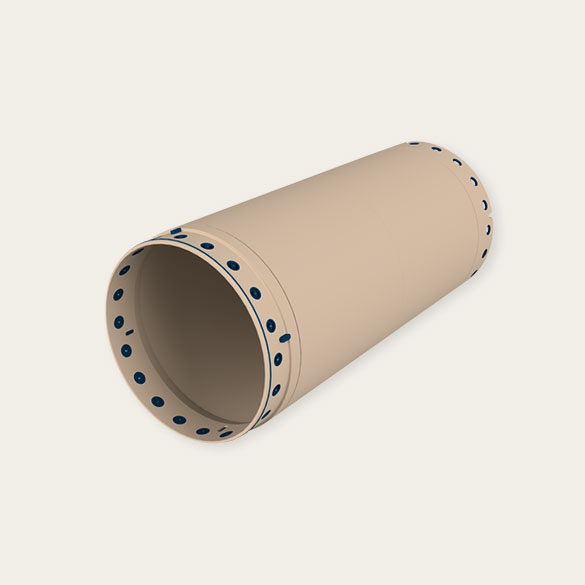

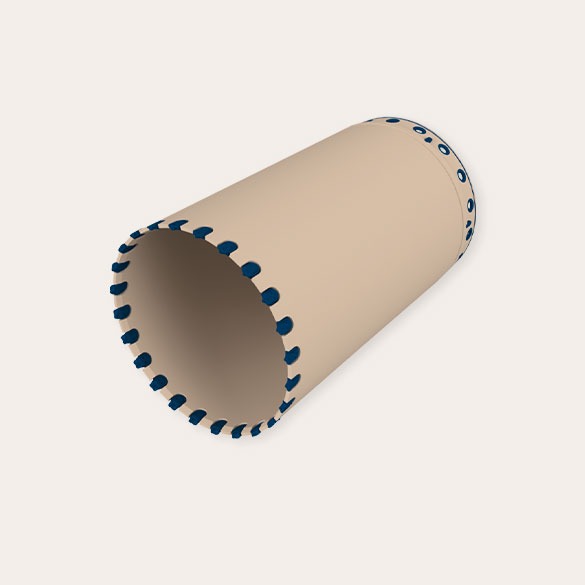

Casings

For cased boreholes, LEFFER offers double-walled casings in different of useful lengths. Our low manufacturing tolerance for diameter, roundness and straightness pays off on the construction site: Precisely fitting casing joints ensure fast, straight placement, bolting and optimum force transmission. The casing joints, consisting of a female and male part, are secured with radially arranged conical bolts. The inside and outside of the casings are smooth throughout their entire length, which prevents the reinforcement cage or drilling tool from getting stuck when pulling the casing.

LEFFER casings have also proven themselves many times over in cased kelly drilling through water-bearing soil layers or in drilling with water ballast. To prevent water and fines from entering the casing, both the cone bolts and the casing joints can be sealed with additional sealing rings.

HD Casings

For cased boreholes greater depths or diameters greater than 1500 mm, LEFFER HD has casings in its portfolio that meet the high requirements for particularly large drilling depths. Reinforced casings joints with backlash-free, conical bolts and larger wall thicknesses reduce wear on the casings joints and also ensure reliable transmission of vertical forces and torque.

| Casings | HD Casings | |||

| 620/540 | 1500/1400 | |||

| 750/670 | 1800/1700 | |||

| 800/720 | 2000/1880 | |||

| 880/800 | 2200/2080 | |||

| 900/820 | 2500/2380 | |||

| 1000/920 | 2800/2640 | |||

| 1200/1120 | 3000/2840 | |||

| 1300/1220 | 3200/3040 | |||

| 1500/1420 | 3500/3340 |

Cutting shoes

Decades of practical experience are incorporated in the design and continuous further development of our cutting crowns. For continuous drilling, the tooth system, i.e. tooth shape and number, contact pressure and the corresponding free cut must be correctly selected. The geology of the ground determines the design of the cutting teeth. Taking these variables into account, LEFFER offers individual cutting crown types for a wide range of requirements.

Tremie pipes and accessories

When concreting there is a risk of the concrete segregating in the downpipe. To ensure a safe concreting process, LEFFER has developed a special HD concreting tremie pipe system: The tremie pipe joints we have designed can resist very high tensile forces, which prevents the concreting pipe string from tearing off, even in case of very long pipe strings. The high-precision, machine-manufactured parts have a high degree of tightness and are therefore also ideally suited for applications in the field of air-lifting technology.

The reduction of individual parts (in contrast to flanged pipes) reduces wear at the joints. Easy to handle, maintain and (dis)assemble, LEFFER tremie pipes NW 150, 200, 250 and 300 save valuable time and thus costs at the construction site.